- Mon - Sat 8:00 - 6:30, Sunday - CLOSED

Overview

- Home

- Overview

An overview of how a Project is carried out

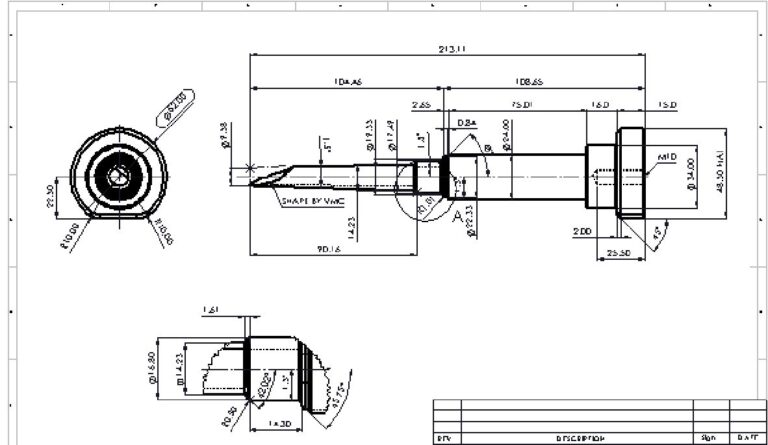

2D/3D Design

This is how we receive our die casting order.

2D/3D Model

Design

Here, our design team designs the die till optimum accuracy.

Design

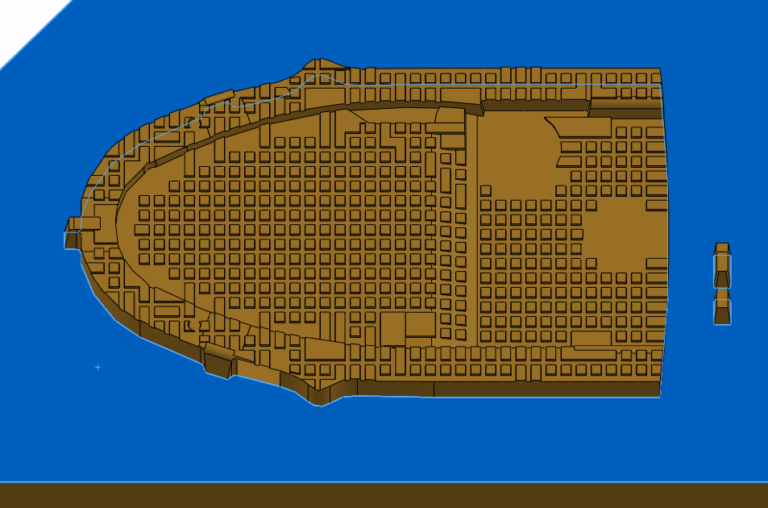

Machining

1. Conventional Machines:

1. ToolRoom:

This includes all die casting process pre-heat treatment. Machine used for carrying out.

2. VMCs:

2. VMCs:

After the Heat Treatment process, dies are further processed for more precision.

EDM/Wire Cut

EDM/Wire Cut

The dies then undergo via these machines, if required, for more précised casting. (That blue and yellow on is EDM and as for WireCut, it is written on the machine itself)

EDM

Wire Cut

Matching & Inspection

Matching & Inspection

The ready die is up for matching on spotting machine (that big one is spotting machine) and it is further inspected for any measurements and errors (those white machines are the inspection machines).

Die Spotting Machine

Inspection

Assembly

Assembly

This is the last step from our side, in which the made die is assembled in such a way that it is ready to use in real-time by the respective companies.

Delivery

Delivery

The die is sent to the company and our work ends here.

- © Copyright 2023 by Arpana Dies